Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Model No.: SN-100

Brand: GEMS

Applicable Industry: Hotels, Manufacturing Plant, Retail, Food &Amp; Beverage Shops, Food Shop, Food &Amp; Beverage Factory, Farms, Restaurant, Home Use

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Hot Product 2019

Core Component Warranty Period: 1 Year

Core Components: Motor

Old And New: New

Place Of Origin: China

Warranty Period: 2 Years

Core Selling Point: Automatic

Application: Electric Milk Churn

Customized: Customized

Material: Sus304 Stainless Steel

Usage: Produce Liquid Yogurt

Capacity: 100l/300l/500l

Feature: Falvored Yogurt

Keywords: Stainless Steel Milk Churn

Packaging: wooden case

Productivity: 100L/batch

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 50 sets/month

Certificate: CE

HS Code: 8434200000

Port: Qingdao,Shanghai,Ningbo

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF,EXW

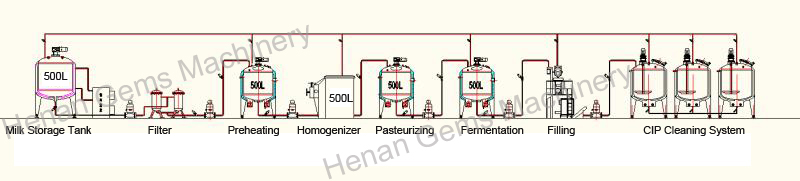

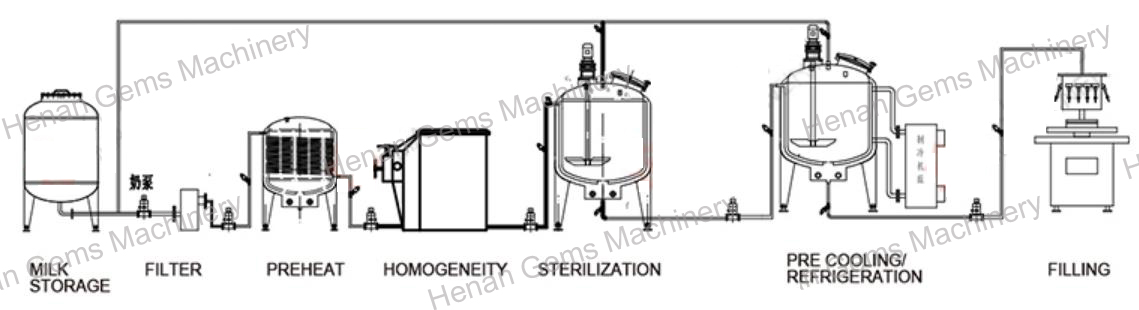

Introduction of Small Scale Milk Yogurt Production Line for Sale

The whole yogurt production line can make various dairy products, such as goat milk, horse milk, soy milk, and fresh milk. The entire processing from the first step to the final yogurt takes approximately 8-10 hours. All tanks are made of food grade stainless steel.

The raw milk is stored in a storage tank, and the temperature in the tank is set to 3-6 ° C. The fresh milk passes through a single filter to filter impurities of the fresh milk and finally enters the preheating tank through the milk pump.

2. Preheating Tank

The main purposes of milk heating in the yogurt production line are as follows:

1). Kill microorganisms that may cause disease

2). Eliminate most other organisms to increase the shelf life of the product

3). Make the protein have a certain degree of denaturation. This improves the consistency and viscosity of the yogurt and prevents the separation of whey.

3. Homogenizer

The benefits of homogenization for yogurt production are as follows:

1) Improved the consistency of yogurt

2) Higher stability for whey separation

3) Yogurt looks whiter and has a more creamy and richer flavor than non-homogenous yogurt

4) Better distribute stabilizers in the system

4. Pasteurizing Tank

Before the fresh milk sterilization process is started, it is necessary to ensure that the water level of the sterilizer is reached at the water level mirror. Set the sterilization temperature (usually set temperature 85 ° C). Turn on sterilization heating, sterilization and stirring. When the milk temperature reaches 85 °C, the device will give an alarm and the sterilization will be completed.

The pasteurized fresh milk is fed into the fermenter through the milk pump. Before the fermentation process is started, the temperature of the fermenter is usually set at 43 ° C, the fermentation time is usually 8 hours, the fermentation heating is started, and the fermentation is stirred. After the milk temperature has reached 43 degrees, the corresponding strain is added and the yogurt is fermented. After 8 hours, the yogurt fermentation process will sound an alarm.

Technical parameters of Pasteurizer Cooling Tank for Yogurt Filling Sealing Machine

100L/batch, 300L/batch and 500L/batch or more, we can customize the line according to the customer's demands.

Customer Design of Yogurt Production Line:

Workshop:

The Yogurt Production Line for Sale is with 500L capacity, we also match CIP cleaning system. Now all of the tanks is upon the base, easy to install. What is more, we also have the Yogurt Production Line, this line mainly includes Milk Pasteurizer, Milk Cooling Tank, Milk Homogenizer, Milk Cream Separator and Filling Machine. Please contact me for details:

Product Categories : Yogurt Production Line

Home > Products > Yogurt Production Line > Pasteurizer Cooling Tank for Yogurt Filling Sealing Machine

Send Inquiry

Mr. Danny Lee

Tel:86-379-67798389

Fax:

Mobile Phone:+8615896588799

Email:danny@gemsmachine.com

Address:No.8, Guanlin West Road,Luolong District, Luoyang, Henan

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.